“The good old days”. A sentence used often to refer to the times when everything was better. While this can be true in certain scenarios, it is far from the truth when it comes to dental treatments. Modern dentistry offers quick and satisfying solutions to every issue, thanks to the improvement of the tools and techniques used. So let’s see how a 3D scanner and printer end up at a dental clinic.

The foundations of modern dentistry

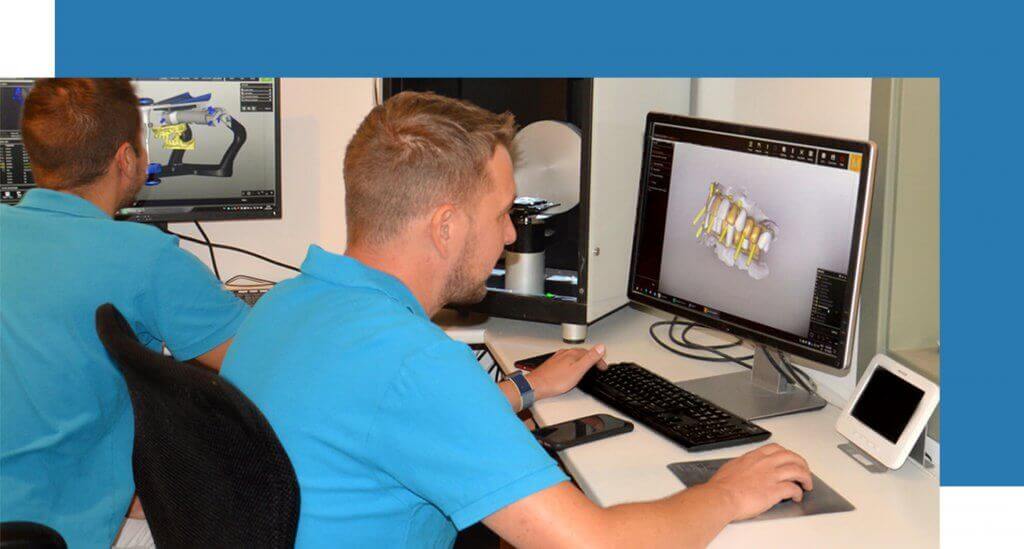

Just like in almost every sector of healthcare, digital technologies are more and more popular in dentistry. This process started 20 years ago, with the appearance of the first CT-scanners. “This is a 3-dimensional scan, which opened up new routes in terms of tooth replacement. You can easily measure vertical and horizontal bone availability on a CT-scan, which is important if you are planning to use dental implants.” says Gábor Szakonyi, Managing Director of VitalEurope. The next big step in terms of digitalization was also in the field oral surgery, when surgeons started using computers to plan the position of dental implants. After measuring the bone, the program calculates the ideal position of each implant, and also provides a template to guide the surgeon during the surgery.

The CAD/CAM (computer-aided-design and computer-aided-manufacturing) method then soon became popular in the manufacturing of metal-free restorations. Nowadays, every modern dental laboratory has a milling machine to carve the artificial teeth out of a block of Zirconium.

Scanner instead of Silicone

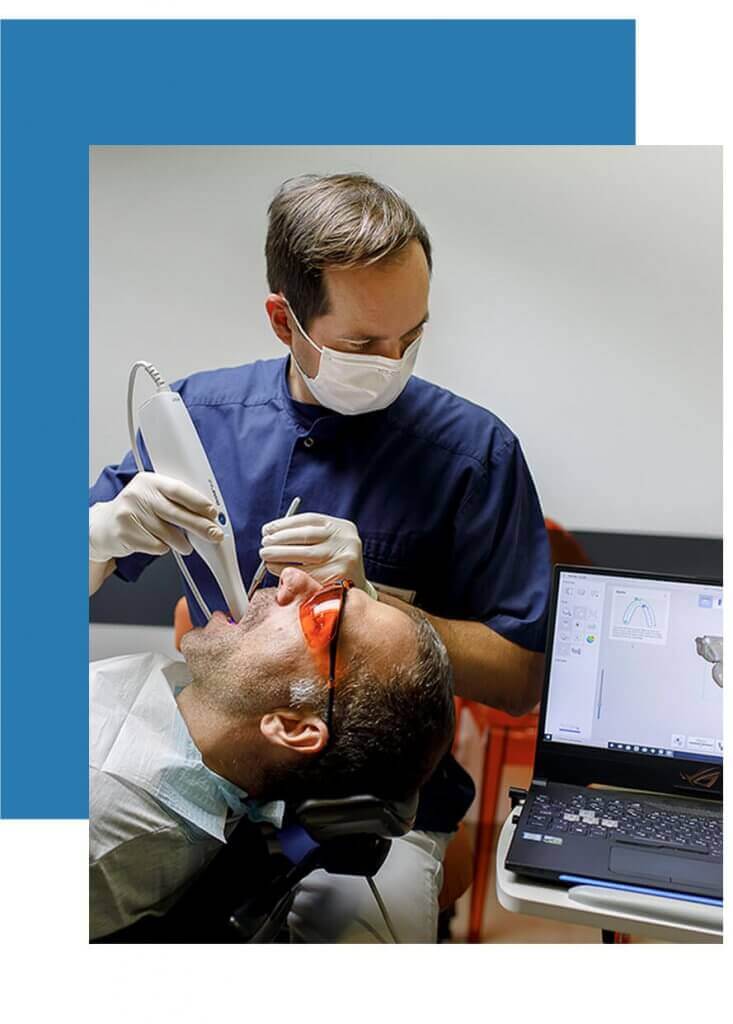

Interestingly, for a very long time there was no alternative method for the most important part of every dental treatment, the impression taking. The process may be familiar to almost everyone: the patient bites down on a metal spoon, which is filled with rubber-like silicone. It takes up to several minutes for this material to harden, providing an impression of the patient’s teeth. “The idea of digital impression-taking only materialized 4-5 years ago. We use a special 3D-scanner (oral scanner), which can fit into a patient’s mouth. It scans all the teeth, and creates a digital image of the scan. However, early scanners were unreliable, as they had difficulties scanning wet surfaces, such as teeth covered in blood or saliva. It took 2 years for this technology to become an alternative method for impression-taking. Nowadays it provides the most accurate and precise results.”

The printed final touch

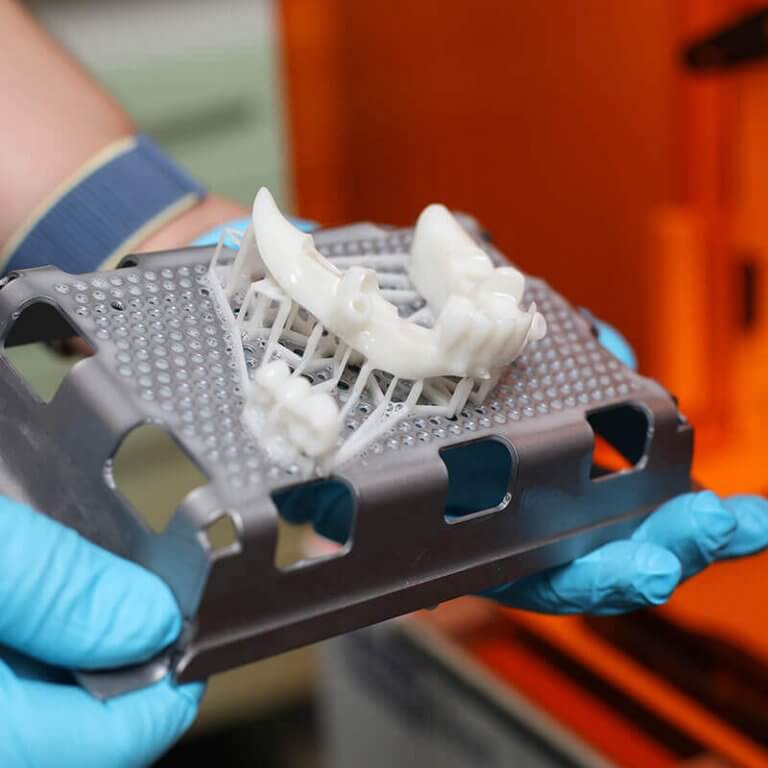

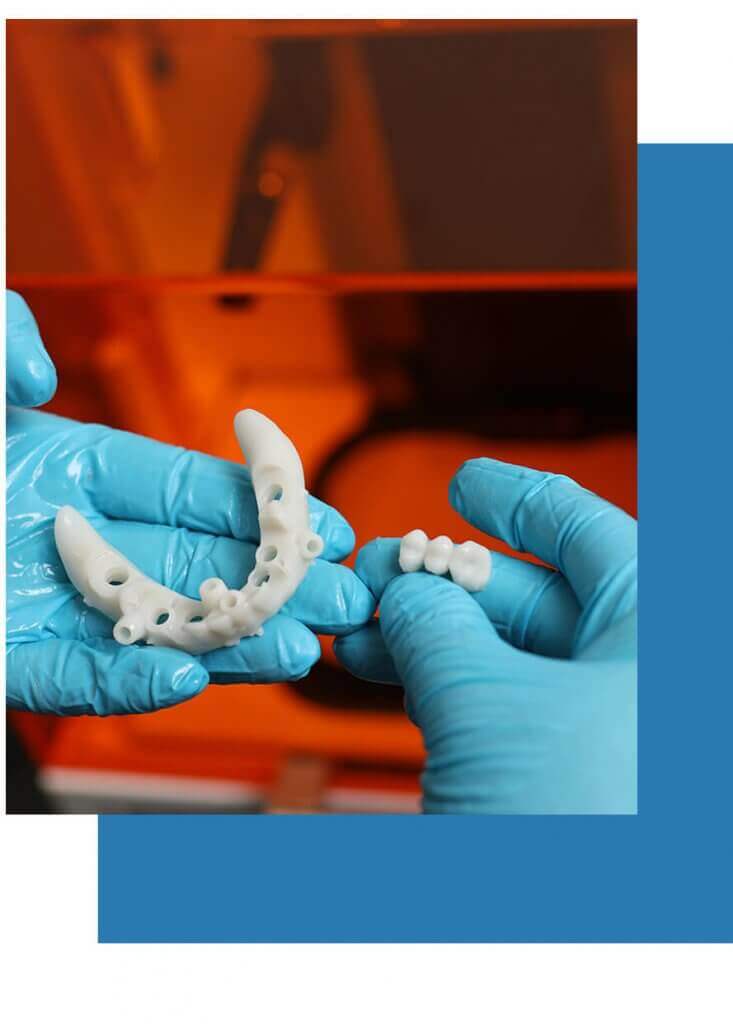

The next step of digitalization in dentistry was the spread of 3D-printers in dental laboratories. Right now, we are only able to print plastic, which means we use this method to create temporary crowns. “A dust like material is mixed with water, which makes it liquid, but more consistent than water. A special laser is used to harden the material, and to give it the desired shape. With the help of 3D technologies we can go through the entire treatment without using the classic analog methods.”

Better than anything else

Without a doubt, these new technologies are better in every way, when compared to their classic counterparts. They provide a more precise, therefore longer lasting solution. In addition, they are a lot faster and more comfortable. “Before these technologies, a patient would have to visit the clinic several times for a single tooth replacement. Today, the entire could be carried out in just three stages. First, we take a CT scan, and a digital impression. Then right after the surgery, we provide the 3D printed temporary solution to the patient, which is later replaced by the finalized version of the crown.” Not only better in every way, but also cost effective, as there is no price difference between old and new techniques. It is clear that the future of modern dentistry is about full digitalization, and we at VitalEurope are trying to turn that vision into reality.